CONVERSION SERVICE

We have been converting paper and board for the packaging industry for over 45 years, offering a wealth of knowledge and experience.

Our team of experienced manufacturers are able to convert many different grades of carton board. We have partnered with all major European mills, providing support services across their ranges, giving us an unrivalled understanding of carton board and its characteristics.

From 100gsm to 600gsm we can convert a wide range of board into a broad selection of sheet and reel sizes.

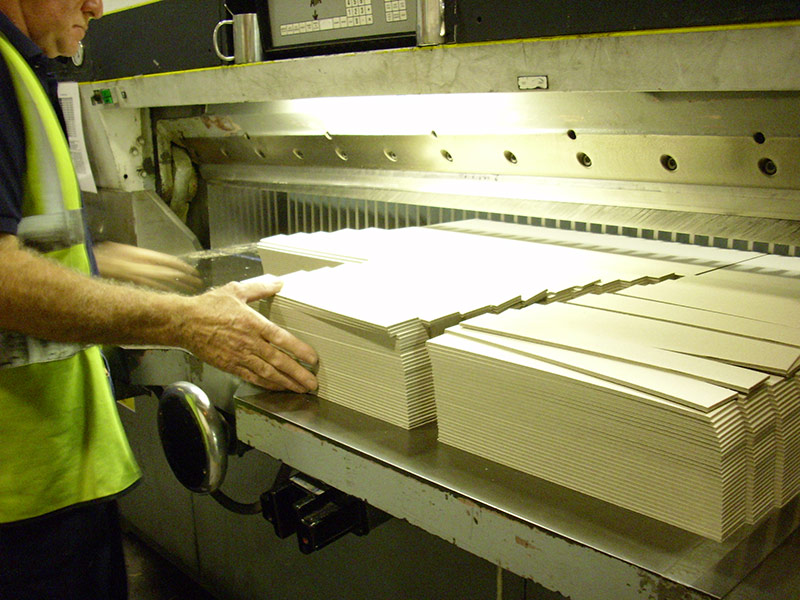

SHEETING

We are ideally positioned as an entry point into the UK for mills wishing to import products in reel format to be then converted for the market to react to the changing demands. We operate three carton board sheeters with a combined annual capacity of 45,000 tonnes.

We also have the unique ability to sheet on our board laminator, adding further flexibility and support to our available capacity.

We are equipped to convert a wide range of boards from 100gsm to 600gsm into sheet sizes from 400 x 420 up to 1600 x 2500.

We offer a unique manufacturing model that gives us fast turn around and high quality, delivered to our customers. For ongoing or short term requirements our key strength is our highly skilled and experienced workforce, which enables ourselves to maximise efficiency and output to offer best in class service.

REWINDING

Our 2800mm width Pasaban rewinder offers mother to child reel conversion services, which increases our flexibility in offering a reel to sheet conversion service for any mill wishing to maximise the decal and reduce transportation costs by importing larger reels.

Offers:

- Ability to resize reels.

- Greater flexibility at the point of sheeting.

- Reel sales if required.

GUILLOTINING AND PALLET TURNING

Our guillotining and pallet turning capabilities offer a valuable upcycling service within the UK marketplace for slow moving or problem stock already delivered from abroad through:

- Cutting standard pallet stock to bespoke sizes.

- Reclaiming damaged pallets from storage or transportations issues.

- Repacking product to the requirements of individual customer.

STORAGE

Large quantities of reels and sheeted pallets are held in stock, meeting all the requirements of both printers and carton makers with guaranteed quality.

Our purpose built reel store and separate pallet storage and dispatch operation, located on the same site as our conversion facility, offer 2,500 tonnes of reel storage and 6,500 pallet spaces.

IT SYSTEM

Our purpose built bespoke IT system delivers a fully integrated solution to anyone looking for a long term service conversion provider. It offers:

- A direct web portal to interrogate our system.

- Push/pull live data to your own system.

- Live manufacturing and dispatch data.

- Bespoke documentation to meet your needs.

- Full traceability.

DEDICATED ENGINEERING TEAM

We have a dedicated on site engineering team responsible for maintenance, upgrades and developmental improvements on all our equipment. We operate a continuous upgrading program to our own equipment to ensure each has up-to-date control and safety systems.

FLEXIBLE WORKING

All our operators work across the plant in all areas, giving us world class machine availability and reduced lead times.

PRODUCT KNOWLEDGE

All our staff have extensive knowledge of materials and the necessary quality requirements for our customers. This gives an unrivalled level of expertise which maximises efficiency and reel to sheet quality.

ENVIRONMENTALLY FRIENDLY

We strongly believe in doing all we can for the environment through the manufacturing process and are extremely proud to recycle and segregate around 98% of our waste.

The foundation of European carton board production is based on continuously growing, well-managed, forest, as well as paperboard mills powered by bioenergy. This renewable raw material enables the production of a product that is both recyclable and energy recoverable.

Boardlink’s key suppliers now power their processes by and produce clean energy from nature, using forest, wind and water.

All our boards are produced with materials that are environmentally friendly and naturally recyclable or biodegradable. All materials come from a sustainable source compliant with the EU timber regulation 995/2010. We hold FSC® chain of custody certification enabling all our range of products to be manufactured using FSC® or PEFC certified material.

Our paper plate material is supplied by a UK mill that uses UK forestry products and is recyclable and degradable. WRAP has classified our board trays as ‘Widely Recycled’. This means that any of our trays can be recycled with consumer paper waste streams, providing there is no food residue remaining in the container.

Throughout production we embrace the green credentials of the industry we are in.